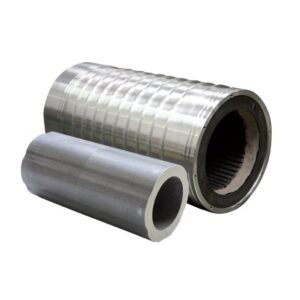

Parker – NK Series – Low Cogging Servo Motor

NK-series frameless servo motor kits are innovative and optimized, enabling the complete integration of a low-cogging direct drive servo motor within a mechanical system. Available with 230/400VAC windings, power ratings to 34kW and speeds to 15000 min-1

The NK servo motor kit is an innovative and comprehensive approach enabling the complete integration of the motor in a simplified mechanical system. This approach ensures that the size constraints of the machine are utilized to maximum effect.

NK-series frameless servo motor kits are innovative and optimized, enabling the complete integration of a low-cogging direct drive servo motor within a mechanical system. Available with 230/400VAC windings, power ratings to 34kW and speeds to 15000 min-1

The NK servo motor kit is an innovative and comprehensive approach enabling the complete integration of the motor in a simplified mechanical system. This approach ensures that the size constraints of the machine are utilized to maximum effect. This delivers a more accurate, reliable and robust solution than traditional construction methods. A complete range of products is available to meet the design needs of many different mechanical systems in a host of different applications. Other more bespoke adaptations can be developed upon request.

Applications:

- Medical

- Tooling Machines

- Marine

- Special Machines

- Electric Cylinders

- Pump

Technical Overview:

- Motor Technology : permanent magnet synchronous servo motor kit

- Frame Sizes : 42mm | 56mm | 62mm | 80mm | 110mm | 143mm

- Power Range : 0.2 ... 7.5 kW (air cooled) / 3,8 ... 34kW (water cooled)

- Torque Range : 0.4 ... 41 Nm (air cooled) / 3,1 … 90 Nm (water cooled)

- Speed Range : 1000 ... 8000 min-1 (air cooled) / 2000 ... 15000 min-1 (water cooled)

- Voltage Supply : 230VAC | 400-480VAC

- Number of Poles : 10

- Cooling : Air-Cooled / Natural Convection (standard) | Water Cooled (on request, NK3-8)

- Protection Level : IP00

- Feedback Sensors : Resolver | Absolute Encoder (EnDat, Hiperface) | Without Sensor

- Other options : Holding Brake (optional)

- Marking : CE

Advantages:

- Compact footprint and reduced weight of the mechanical systems

- Reduced cost

- Direct Drive: accurate and robust mechanics

- Complete and optimized solution including sensor, cooling system and drive

- Integration assistance

Certifications

UKCA Certified