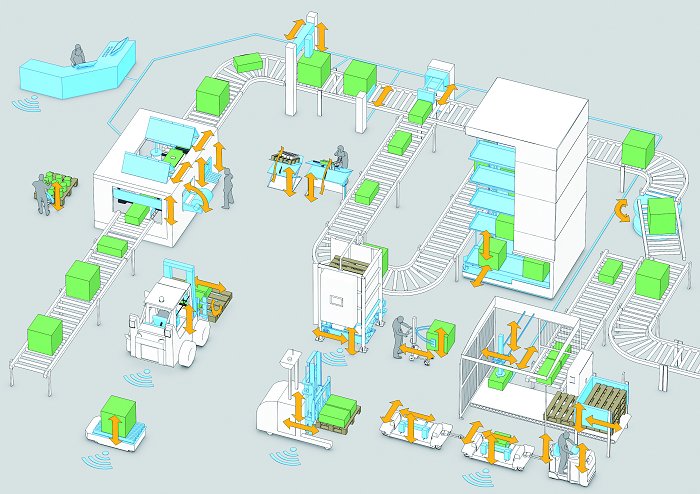

Figure 1. Forward-thinking factories incorporate multiple of interconnected machines and devices that take advantage of advanced actuator features to enable a fluid, synchronized and safe manufacturing process. These uses can include forklifts, assembly/control stations and fixtures, AGVs, and components that can be easily and quickly adjusted on the fly.

Factors impacting industrial motion

- Physical properties. Material handling automation developers must consider the shape, weight, size, position, and direction stability of packages moving along a plant or conveyor system. They also must consider how the package materials affect their rollability, slide-ability, stack-ability, surface sensitivity, and stiffness.

- Environmental parameters. Material handling equipment designers must consider parameters such as room layout, machine size limitations and available degrees of freedom.

- Motion parameters. Like most motion control applications, material handling applications consider weight and inertia of the payload as determined by speed and acceleration within cycle times and the required accuracy.

Material handling applications may also require special attention to kinematic factors such as drift, overshoot, stabilization time and interchangeability, with particular attention to the drive, power transmission system, position measuring system and bearings. Friction can lead to play in the bearings, poor resolution of the position measuring systems, structural static deformation. Dynamic flexibility can contribute to neural weaknesses, which can lead to errors and failures. Equipment designers must address all these factors within the context of maintenance, safety and durability.

Electric linear actuators have been used in material handling operations for many years, and during that time, there have been advancements, optimizing them for supporting new industrial operations. These advancements include:

Heavy load handling – Electric actuators can now handle heavy duty loads up to 25 kN, which have previously been relegated to hydraulic or pneumatic cylinders. These improvements are due in large part to component material improvements and advancements in ball screw technology, such as implementation with ball bearings.

Extended stroke lengths – Electric linear actuators are now also capable of longer strokes, tackling applications that hydraulics and pneumatics had previously dominated. Where electric linear actuators had previously been limited to 300 or 400 millimeters, they can now span up to 1.2 meters.

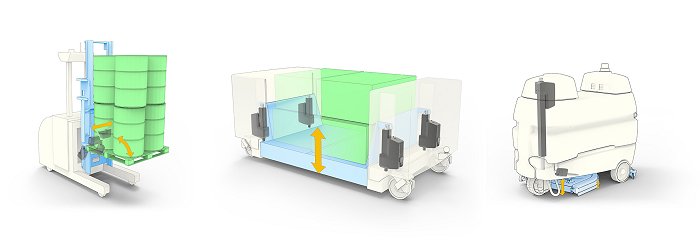

Compactness – Actuators are often designed into confined spaces. On a packaging line, for example, feeding and cutting systems may compete with other units for space. On an AGV or forklift, space is always at a premium, and actuator size can also impact energy usage. Actuators with housing the size of a passport can now handle loads up to 2000 N (450 lbs.) They fit into small spaces for which previous-generation actuators would be either too large or weak.

This compactness and simplicity are a major difference from hydraulics and pneumatics, which require an imposing infrastructure of equipment such as pumps, hoses, valves, reservoirs and compressors. Electric actuators simply plug into a power supply and connect to a network. The integration of a PLC allows for more efficient and seamless control of electric actuators, resulting in reduced downtime, increased productivity and cost savings.

Intelligence – Electric linear actuators are now available with modular onboard controls that enable simple on/off switches, low-level switching, position feedback and CAN bus network integration. They can monitor and control, diagnose, read position and operating statistics in real time, and be fine-tuned on the fly. (Figure 2)

Figure 3. For AGVs without human involvement, remote control over radio, WiFi, satellite and other communications is vital. In addition to their remote benefits, electric actuators reduce maintenance and environmental concerns thanks to sturdy designs. This all-in-one actuator package makes it possible for AGVs to move goods over larger areas no matter how demanding the conditions.

Linear actuators using brushless motors can have duty cycles of 100 percent and up to 600 km (375 miles) of maintenance-free life. This long life is a major advantage over hydraulic and pneumatic technologies, which require almost constant maintenance.

Plus, lubrication technology has advanced to the point where some actuators are factory lubricated for life.And adherence to IP standards of IP65, IP66 and IP69K prevent particulate, moisture and other ingress that can shorten life.

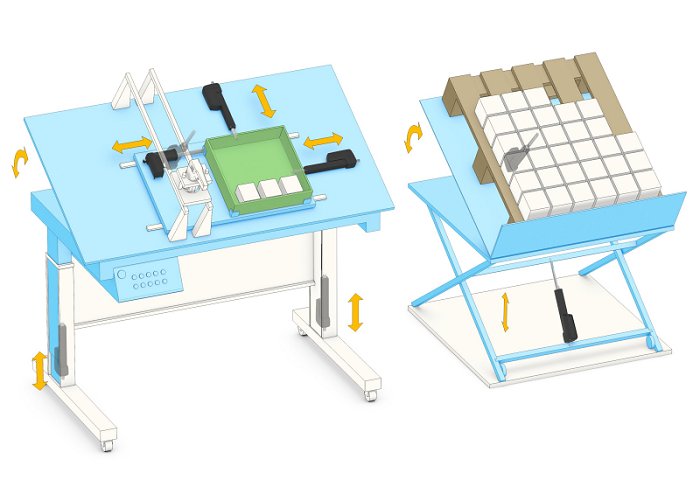

Safety and ergonomics – Material handling equipment constantly puts humans at risk. For example, a machine that loses power may drop its load faster than a human can get out of the way. There might be ergonomic challenges resulting from repeated movements or awkward workpiece positioning.

Electric linear actuators aid in these situations with electromechanical and static holding brakes, which hold the load in place in case an application loses power. They can also make work safer by raising, lowering, or tilting worktables to comfortable, more ergonomic angles.

What’s the return?

To calculate the most accurate ROI with the right amortization on a custom project for both the OEM and the end user, designers must make procurement decisions in the context of the entire product lifecycle, including production costs, ongoing operating costs and potential productivity. Likewise, the decision should factor in the benefits of integrating the latest technology, such as onboard electronics, which contribute to greater competitiveness for the OEM and benefits for the end users.