Parker – HKW Series – Frameless Spindle Servo Motor Kit

HKW-series frameless spindle motor kits are designed for direct integration within the machine mechanics and offer high torque at slow speed and very high speed at constant power. With 400VAC windings, power ratings to 230kW and speeds to 50000 min-1

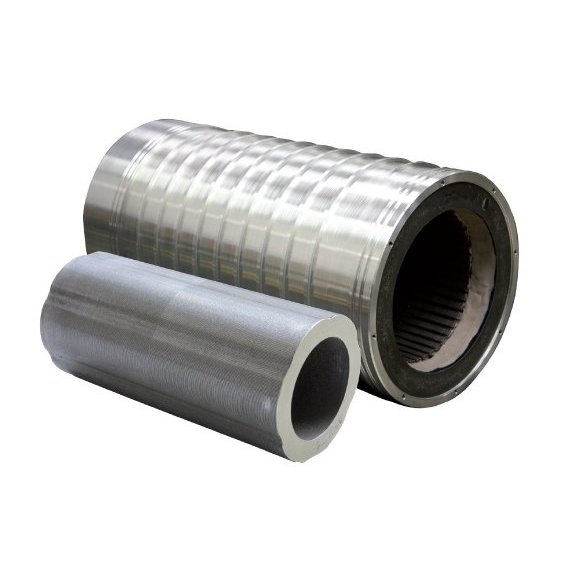

HKW motors are high performance permanent magnet synchronous servo motors for spindle applications up to 230 kW. Delivered as separate components to be integrated into the mechanical structure of the machine, HKW motors benefit from the use of field weakening, in order to achieve both high torque at slow speed, and very high maximum speed at constant power.

HKW-series frameless spindle motor kits are designed for direct integration within the machine mechanics and offer high torque at slow speed and very high speed at constant power. With 400VAC windings, power ratings to 230kW and speeds to 50000 min-1

HKW motors are high performance permanent magnet synchronous servo motors for spindle applications up to 230 kW. Delivered as separate components to be integrated into the mechanical structure of the machine, HKW motors benefit from the use of field weakening, in order to achieve both high torque at slow speed, and very high maximum speed at constant power.

Applications:

- Tooling Machines

Technical Overview:

- Motor Technology : permanent magnet synchronous servo motor kit

- Frame Sizes : 85mm | 108mm | 155.5mm | 195mm | 242mm | 310mm

- Power Range : 2.3 ... 230 kW

- Torque Range : 4.2 ... 1250 Nm

- Speed Range : 260 ... 23200 min-1 (base speed) / 16000 ... 50000 min-1 (max speed)

- Voltage Supply : 400-480VAC

- Number of Poles : 4 | 6 | 8 | 16

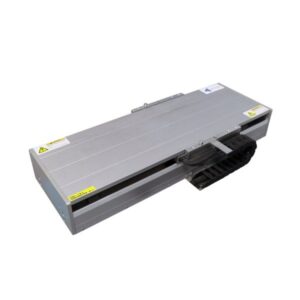

- Cooling : Water Cooled (standard) | Air-Cooled / Natural Convection (on request)

- Protection Level : IP00

- Feedback Sensors : Without Sensor | Resolver (optional)

- Marking : CE

Features:

- Kit solution leading to simplified mechanical design

- Very high speed capabilities - up to 50 000 min-1

- Constant power operation up to 10 x base speed: no oversizing of the drive

- High dynamic performance and power density - increased productivity and reduced size compared to induction motors

- Cold permanent magnet technology - reduced heating in the bearings compared to induction motors, no dilatation effect

- Compatibility with third-party drives - Siemens / Fanuc